Maintenance/Upgrade:

After 11+ years of high underhood temperatures, the

original Fuel Injection

wiring harness and the AMP electrical connectors

that snap onto the Fuel Injectors had become brittle

on my 1989 XJ-S V12.

At some point, this needed replacement,

however, the real impetus for making this change started with

an incident that could have been a disaster.

My wake up call came one day when

the car started losing power and backfiring like a cannon.

This had happened a couple of times to a lesser

degree before, but "mysteriously"

cleared itself up.

This time, power dropped off to nothing and

a whiff of smoke seeped from under the bonnet. Oh No!

If you have had this happen with your car, you may be having

the same problem so read on.

Immediately stopping the car and opening

the hood, the (USA) drivers side catalytic converter was glowing

a bright yellow-red!

Later I was to find that one or more of the Fuel Injector

Electrical Connectors had come loose,

an injector(s) wasn't firing, and as a result, the ECU

saw the B bank go lean and increased more fuel to the other cylinders. The

excess fuel came out the exhaust manifold and was burning in the cat. This

is one way underhood fires can begin in an XJ-S.

Getting the car back to the house for examination,

it was running rough on the "B" bank.

By unplugging one injector connector at a time, it was easy

to determine which injector was not firing as removal made no

difference in engine roughness.

Curiously, desptite the AMP electrical connector to the injector feeling

like it was snapping

onto the injector, the problem did not

always clear up. Therefore, that connector's

inablity to always make a solid connection to the injector

was suspect. Replacing just the connector would be penny

wise but pound foolish.

A new harness would be expensive. The Jaguar dealer wanted around $1,200 USD

and prices on the Internet ranged from $850-$1100. However reports

of other XJ-S owners on the Jag-Lovers.org XJ-S "list"

had reported making their own harnesses

for substantially less. The project was worth investigating, and could

also be fun and save a lot of money too.

For fans of this web site, you know that I also seek form

to follow function, so there was a second motivation for making

my own harness. After giving it some thought,

I realized it was possible to hide this wire loom out of

sight and also protect it from prolonged

subjection to extreme underhood temperatures.

First, a little background on the configuration of

the stock fuel injector harness.

All the wiring for the fuel injectors

comes from the Engine Control Unit in the trunk (ECU)

through the passenger side firewall (U.S. version cars) to a wiring bundle

running along the top of the right wheel well, terminating

in an eight pin female connector. There, an

eight male connector plug that terminates the loom of wires up

into the vee of the engine

connects to a female plug.

This connection point is

hard to see by casual observation because the air cleaner assembly is

slightly in the way. Yes, that's it--the dull yellow white plug

covered in oil and gunk.

From this connector, the loom runs underneath the air conditioning compressor,

under the bellows-like cruise control sitting on the front center

of the Vee of the engine, and up to the left and right banks to

each injector.

In a stock XJ-S, most of this would be hidden out of sight, but with my

engine beautification project,

I did not want these wires to continue to be exposed.

Also, continuing to let wire lay

on top of the vee of the block cooking in the center of the engine

did not seem like a good idea.

My solution was to

double back the wires for the new harness

from the main connector plug

along the right fender well

and the firewall to feed through the back of the vee

of the engine.

In addition to the visual aesthetics in doing so, it would

reduce the amount of heat that

the harness would be exposed to over time.

These types of changes, while appearing easy, never are,

as other unforeseen details always

pop up, complicating the project.

One was the direction that the F.I. electrical connectors were pointing.

Cylinders are numbered from front to back (i.e.

1 through 6). Cylinders 1, 2, and 3 had connectors pointing towards

the front of the engine, but the back three connectors

were pointing towards

the back (firewall.) Interesting, odd, and unacceptable.

I decided to change all the injector connectors to face

towards the back (firewall) since that's from whence the new harness

wires would come. However this by neccessity demanded a whole

other project with removal of the fuel rail,

injectors, and

replacement of the Fuel Injection hoses.

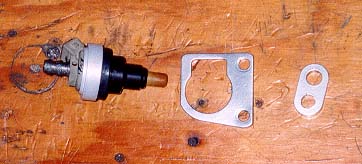

The reason is that the hold down plates for

the injectors are keyed to point either forward or

backward. They can not be switched around without cutting/removing

the FI hose. (See the notch in the picture below and how it fits

in with one side of the injector):

Steps to Rebuilding the FI Harness

Steps to Rebuilding the FI Harness

After disconnecting and

removing the old harness, start with cutting off the main

8-plug connector. Leave enough wire to work with and strip

the ends so that later these ends can be melded into the new

wiring of the harness. This plug is

probably filthy dirty with oil and

dirt and a good washing

in Dawn Dishwashing Detergent will

clean it up to an off white color.

After disconnecting and

removing the old harness, start with cutting off the main

8-plug connector. Leave enough wire to work with and strip

the ends so that later these ends can be melded into the new

wiring of the harness. This plug is

probably filthy dirty with oil and

dirt and a good washing

in Dawn Dishwashing Detergent will

clean it up to an off white color.

Purchase new Wire

The local Napa Auto Parts store had

plenty of colored "hook up" wire available in several colors

(an important consideration as you will see.) The colors

you will need are listed below. Although not

"high temperature" the box said it was good up to over

220° F. Considering that the new route took it out of the arduous conditions

of the center vee, this seemed reasonable replacement and

at least on par with the original wire. I also upgraded the gauge

thickness from the standard 18 gauge to 16 gauge for a more solid

electrical signal to the injectors. I also did this because of the way

I would change the stock configuration and "tap" onto each wire (details below.)

Buy New AMP Connectors

Sourcing the replacement AMP (brand) connectors was a bit more difficult.

I tried looking on the Internet for many

hours without luck searching auto parts dealers, the AMP site,

auto electrical supply sites for "Jaguar XJ-S" "V12" and the like,

and by using the cryptic numbers stamped on

the side of the injectors to no avail.

The local NAPA Parts guy swore that he had seen injectors

and the associated AMP connectors like

the Jag V12's before on another car, but without a part number,

it was a shot in the dark to locate it.

Sourcing the replacement AMP (brand) connectors was a bit more difficult.

I tried looking on the Internet for many

hours without luck searching auto parts dealers, the AMP site,

auto electrical supply sites for "Jaguar XJ-S" "V12" and the like,

and by using the cryptic numbers stamped on

the side of the injectors to no avail.

The local NAPA Parts guy swore that he had seen injectors

and the associated AMP connectors like

the Jag V12's before on another car, but without a part number,

it was a shot in the dark to locate it.

Yet again, fellow Jaguar owners, this is simply a

car, not some sacro sanct special piece of equipment

available no where else on the planet. Parts come from general auto sources,

not just Coventry.

To add insult to injury, my counterman went onto say

that this "standard" AMP connector

and the actual injector are about 60% less if listed for

a non-Jaguar. This was half right.

According to fellow Jaguar enthusiast Ed Sowell,

the NAPA part number is 2-17411 and costs only $1.35 USD.

(see Ed's injector rebuild notes at

http://home.adelphia.net/~sowelled/ed/engine/injharness/harnessindex.htm)

I wish I knew this before plunking down over 10 times more

for the "real" Jag part. At least mine has matching rubber

boots and new 1A, 3C type tags for each cylinder--a hefty

premium for what I paid.

If you own a Jaguar, you know the drill. They see you

coming and dollar signs appear in their eyes.

I finally had to resort to calling Jaguar vendors.

I am ashamed to write I can't remember the vendor(s) I got them

from, but they are available, although many Jag suppliers had to be called

before finding one that carried the item.

A set of 12 cost around $100. Be sure the set you get includes the

rubber boots that slip over the plastic connector and the numbered

cylinder rings. For that kind of money--they better.

The parts numbers are:

- AMP Fuel injection Electrical Connector: Part # 15M99031

- Fuel injection Boot Cover: Part # 15M99021

Determining The Wiring Configuration

With the wire and connectors in hand,

it was time to start the project.

In removing the old harness--and I'm exageratting here--it was so

stiff and brittle, you could almost hold it up sideways

and have it stick straight out, looking a little like a Charlie

Brown Christmas tree.

With the wire and connectors in hand,

it was time to start the project.

In removing the old harness--and I'm exageratting here--it was so

stiff and brittle, you could almost hold it up sideways

and have it stick straight out, looking a little like a Charlie

Brown Christmas tree.

After removing the harness, an exacto knife cut away the

now hardened outer sheath.

The big surprise was that each bank (6 cylinders) used only four wires,

thus, twelve cylinders were "fed" by only eight wires.

Interesting. After cutting open and documenting the stock F.I. wire

harness, it all made sense.

Each side of the engine ("A" and "B" bank) has two sets of wiring connections that

tie into three alternating cylinders. One set handles cylinders 1/3/5 and the other

2/4/6. Since each side has only four wires to "feed" six cylinders, it was

becoming clear that some of these had to be wired in tandem.

Each bank has two (for lack of a better term) "ground" wires (see below chart

and diagram.) One ground is shared

with 1/3/5 and the other with 2/4/6. Each ground wire is the same color

code (pink/black on my 1989 Marelli car). The other two wires are distinct colors

per side. Here is the breakdown of how they are wired:

| Cylinder Bank Side |

Connects to Cylinders |

Color |

| A |

1/3/5 |

Orange/Blue,

Pink/Black(i) |

A |

2/4/6 |

Orange/White,

Pink/Black(ii) |

| |

| B |

1/3/5 |

Orange/Slate,

Pink/Black(i) |

B |

2/4/6 |

Orange/Green,

Pink/Black(ii) |

Eight (female) pins from the harness to the injectors

plug into the

main male connector plug. The following diagram documents how

each of these eight male connectors routes to the corresponding

cylinders. This view is looking into

the male plug, i.e. the connector going to the injectors.

[Note: The black

dot is a rubber dummy male plug and is not wired and the lower left location

is vacant:]

Logistics and Wiring Things Together

Logistics and Wiring Things Together

As there are four wires per bank of the engine (A and B sides), I used

cable ties to bind these small wire bundles together.

I even labeled each four wire bundle with a piece of

paper "A" and "B" so that when referencing my cheat sheet, I knew

I was working with the right wire on the correct cylinder.

The last thing I would want to do is go through all this work, put

it in the car for it to be wrong.

Each of

the four wires is connected in tandem to three cylinders. In the original harness,

this was handled by running one wire to come up to a point right before

the front most cylinder

and stopping. [See Picture Here]

From there, three other wire points met it, continuing on to each respective cylinder.

So in essence, the same wire was being double run up past most of the cylinders!

This made for a bulkier set of wiring.

Each of

the four wires is connected in tandem to three cylinders. In the original harness,

this was handled by running one wire to come up to a point right before

the front most cylinder

and stopping. [See Picture Here]

From there, three other wire points met it, continuing on to each respective cylinder.

So in essence, the same wire was being double run up past most of the cylinders!

This made for a bulkier set of wiring.

In my harness, I ran just one wire down past each

of the injectors and tapped into the wire as it passes each AMP connector.

Using the now removed

fuel rail as a measuring stick for spacing,

I stripped the wire sheathing about ¾ inches where the wire passed the injector.

From there, I took one of the

the AMP connector (white wires--see previous picture or

right click here for pic)

and tapped it onto

the new loom wire by first weaving it firmly around the exposed wire,

securing it with some solder, then wrapping that tightly with electrical tape.

Here is a rough diagram

of my "tee" connector:

Using six different colored "hook up"

wires make it easier to keep track of what was what

by color coding them to the stock wire as follows:

NEW ORIGINAL COLOR

Pink = Pink/Black (i)

Black = Pink/BLACK (ii)

Orange = ORANGE/White

Blue = Orange/BLUE

Green = Orange/GREEN

Slate = Orange/SLATE

Having the wires color coded made things a lot easier. Using the wire/cylinder

correlations above, and also working with similar colored wire helped

to see which wires on each bank connected to each F.I. connector.

Remember that if you chose to re-route the loom as described

here, the wire runs will be much longer, and this needs to be

taken into account when creating your new F.I. loom.

The initial plan was to cut all the wire runs to be just long enough

to meet at the main connector plug and connect all eight

wires to the 8 connector male plug.

This proved impratical for

several reasons. For one, I kept messing up portions of wire and had to cut

off pieces and start over. Second, in order

to keep the "A" and "B" side wires sorted out on the work bench

and for neatness in all these strands meeting at the main connector, it was

apparent that it was easier to do all the splicing and wiring

by the AMP connectors first, then take all eight wire ends and

slip on the heat shrink tubing last as the main connector was

braided into the new wiring.

Once all eight wires were

soldered securely, I then bound the

four wires per bank in separate heat shrink tubing for

both neatness and identification purposes.

This way I could tell if I was working on the "A" or "B" bank wiring. For extra protection, I then slipped

an even larger shrink tubing to cover up all eight wires where it butted up against the main connector.

I did not bother using a hair dryer to shrink the wires;

the engine did a good job of that just driving around a day or so.

Now it was time to connect the AMP units into the loom for the "A" and "B" banks.

The wires that are attached to the AMP unit are quite long--long

enough to attach to the colored hook up

wire where the harness would be running from the back to

the front of the engine. In many cases when

the same wire would be continuing pass a cylinder forward,

I simply cut away about a 1/2" portion of the

wire cover right at the vicinity of the injector, then

took the appropriate white wire coming out

of the AMP and wrapped/tied it onto the copper wire.

I put a little sodder

on for good measure, then neatly wrapped it in electrical tape.

The connectors were essentially

'tapped' onto the appropriate wire for that cylinder.

The end result: The harness laid much much

more naturally in the engine and was much less bulky.

One small but potentially important note. If you look at the original and new AMP

connectors you'll notice that one white wire comes out the 'left' side of the top

of the unit, the other the 'right' side; depending how you hold it.

Look carefully and you will see a small "+" symbol

on one side of the injector. Connect that to the power

wire and the other side to the ground.

You certainly didn't want to go through all this and have it not work.

Final Steps

Once all of the AMP units were wired in, I used a (black)

wire loom cover to cover the exposed

colored hook-up wire. These wire covers are inexpensive, comes in

different sizes for different thichnesses

of wiring to cover, and are readily available at most

auto parts stores.

|

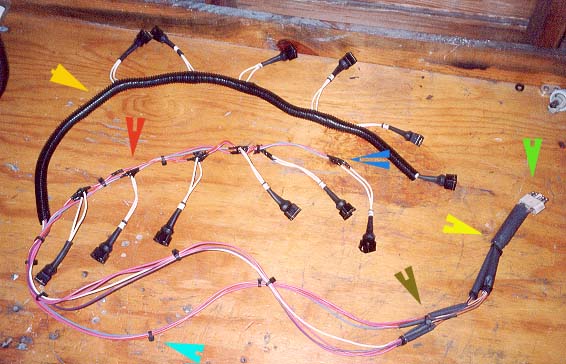

Wire Loom Picture and Legend

|

|

BRIGHT GREEN: 8 pin male main harness connector

YELLOW: Shrink wrap tubing

KAKHI GREEN: More shrink wrap tubing

TURQUIOSE: Cable tie to bind strands together

RED: "Tee" connection tapping into wire

BLUE: Extension to forward (#1) cylinder

GOLD: FLexible coil split wire sheath covering

|

Conclusion

The result, as you can see , is a fresh, custom wired F.I. wiring

harness that has improved the appearance of the engine compartmetn and should easily last

another 10-15 years. The project is fun, low costy, and easy to do,

just requiring time, patience, and a place to work. Total expenditure

was modest and significantly less than buying a replacement

harness:

5 rolls or wire @ $6.45 a roll = $32.25

1 Dozen AMP FI Connectors = $112

1 wire loom package, ½" diameter = $4.00

1 wire loom package, ¾" diameter = $4.00

TOTAL = $152.25 USD

I hope that this article has helped you with your Jaguar, and if so, would you

please sign my

Guest Book and let me know? Thank You.